Woodworking Bench Vices For Best Workpiece Clamping

Updated: 07/04/2021

If pro or amateur, you often come up with a situation where you feel your hands are not just enough to cope with the challenges you face during your work activities. To deal with such cases, there is a tool called a woodworking bench vice to assist.

Multi-Purpose Clamp Tool

This bench clamp equipment assists and supports you in a wide range of scenarios where you need extra hands. A bench vice is a simple, inexpensive, and multi-purpose tool with a wide range of applications in various fields of life.

DIY Drilling And Cutting

Whether working in a workshop, hardware store, garage, or industry, having a small bench vice will significantly help you make your task much easier for you. In addition to professional work, it also has excellent utility in DIY scenarios such as sanding, sawing, chopping, drilling, etc.

Clamping Device For Joiners

A carpenters vice is a mechanical clamping apparatus attached to a workbench with the help of bolts. Depending on the type and nature of work activity, a bench vice can be attached on top, bottom, or a workbench side.

: Silverline Tough Casting Woodworkers Vice

The Bench Vice To Suit Your Work Activity

A table vice is specifically designed to hold a workpiece in a fixed, stable position to firmly remain in its original place while performing the work activity. If you want to increase your workplace's functionality, then having a good bench vice will help you in this regard.

Knowledge Of The Utility

However, purchasing a cheap bench vice that best suits your work activity is not that simple as it seems to be. Several factors determine the utility of bench vice for different work activities. Therefore, having a basic knowledge of all those factors is very important for choosing an ideal bench vice for yourself.

How Does A Bench Vice Work?

All bench vices are composed of some critical components. Each of these components has significance in working a bench vice. A workshop vice consists of a screw, a slide, a handle, and a pair of jaws.

Screw Mechanism Function

All bench vices operate on a screw mechanism that allows the jaws to open and close as and when required. Jaws are designed for holding a workpiece firmly in place, thus allowing the worker to execute his job in a more precise manner.

: Axminster Carpenters Vice Quick Release

What Can The Vice Actually Hold Secure?

A heavy-duty vice primarily depends on the quality of jaws it has and the amount of grip it offers to a workpiece. Therefore, most of the time, bench vices come with jaws that have an additional rubber covering that keeps the workpiece firmly in place and protects it.

Vices Do Come With Jaws

The jaws of a work vice are attached to the slide, then the slide allows the jaws to move back and forth. Screw and handle work synergistically to move the jaws along the slide.

Behave As A Solid Surface?

This means that when the handle is turned, the screw will also shift. This movement allows the jaws to move along the slide towards a workpiece to hold ii firmly in place for power drilling tasks.

Besides holding a workpiece, a bench vice can also act as a solid surface to be hammered against. This increases the utility of bench vice for various other work activities.

Bench Vice Sawing And Welding

A woodworking bench vice is a valuable piece of equipment extensively found in various types of workshops. Either you are sawing in your shed, welding in your workshop or in your garage. You can't deny the significance of having a bench vice in your work activities.

: Eclipse PRO Sliding Jaw Woodworking Vice

Specialised Clamp Work Activity Like Sanding

There are several types of bench vices commercially available, where each class is designed and specialised for a particular purpose. However, all these types can assist you in work activities like welding, drilling, sawing, and sanding.

Electronics And Jewellery

Some mini versions of the portable vice are also available that are specialised for more delicate work activities like repairing electronics and making jewellery. Some bench vices come with built-in pipe jaws that are used for holding round objects and pipes.

Similarly, some bench vices also have a different anvil that provides an extra flat surface to the users to carry out the hammering activities.

How To Choose A Brilliant Bench Vice

As bench vices come in different styles and designs, a user needs to know precisely the scope of his work activities before buying a bench vice. Several factors need to be considered before buying a bench vice.

Typical Bench Vice Dimensions And Expense

The size of a wood bench vice is an essential factor that needs to be considered before purchasing a bench vice. If you have a limited workspace, then it is better to look for a compact bench vice. A bench vice also varies with size; more minor bench vices are usually inexpensive compared to larger ones.

Household DIY Or Expert?

Bench vices anywhere up to 12 inches or even more are commercially available in the market. More minor bench vices are usually meant for household DIY activities. In contrast, more significant bench vices are extensively used in industries.

Weight Of Your Bench Vice

The weight of a swivel vice is also essential to consider before buying it. Bench vices vary in their weight depending on the type of material they are composed of. It is preferable to check whether the workbench is capable of bearing the importance of a heavier bench vice or not.

Strong Heavy-Duty Material

If you purchase a bench vice for hammering purposes, make sure that it is composed of heavy solid material with a sizeable anvil to easily withstand the hammering force.

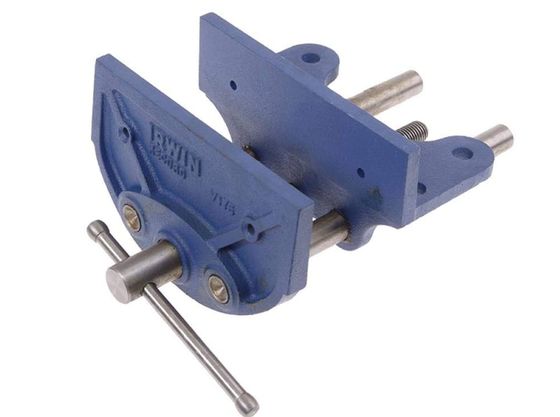

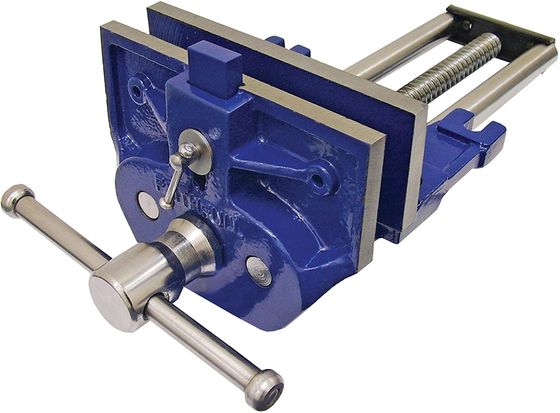

: Irwin V175B Record Woodwork Vice 175mm

Types Of Engineers Workshop Vice Needed

Heavy-duty bench vices are usually composed of a rigid heavy material, particularly iron, to withstand the most severe applications. Commercially they are available with different names such as engineers vice, machinists vice, workshop vice, etc., due to their wide range of application in various fields of life.

360 Degrees Swivel Function

Serrated steel jaws, an exact slide bar and then threaded screws are vital components present in the ideal drill press vice. Usually, heavy-duty bench vices are stationary; however, vices with a 360-degrees swivel are also available in the market.

A user needs to look for essential features like the presence of a 360-degree swivel base and replaceable jaws before buying a heavy-duty bench vice that best suits his interests.

Professional Woodworking Tasks

These vices are widely used by professionals to carry out their wood-related activities. They consist of two jaws; one is fixed while the other is moveable. These jaws are primarily meant for clamping large pieces of wood in place while carrying out work activities.

: AmTech Tools Wood Worker Bench Vice Clamp

Attach The Vice Equipment On Top Or Bottom

Jaws used in these vices are either composed of metal, wood, plastic, or any other suitable material. In the case of woodworking vices, no bench vice needs to be attached to a workbench. However, if work activity demands, it can either be stuck on the top, bottom, or side, depending on a woodworker's feasibility.

Replacing The Vice Jaws

Most of the woodworking machine vices are available in the market with replaceable jaws. This feature allows the users to replace the jaws as and when required depending on the work activity.

Extensively For Hard Materials?

These vices are usually known as engineering vices because of their wide range of utilities in engineering work. They are extensively utilised for heavy-duty metal crafting and cutting; therefore, manufacturers prefer to use a rigid, inflexible material to strengthen the built of such vices.

Quality-Related To Price

Cast iron is the most commonly used material for the production of these vices. In some models, steel iron is being used to build the channel bar of these metalworking vices. However, cast iron is prioritised due to its rigidity, strength, abundant supply, and, most importantly, its low price.

: Draper Zinc Plated Carbon Steel Bench Vice

Fixing The Workbench Securely With Bolts

Metalworking vices have decentralised jaws - which makes replacement easy when worn out. Moreover, soft pads are mounted on the jaws to protect the integrity of delicate articles. Most metalworking vices work on a nut-bolt mechanism due to their heavyweight.

Vice Equipped With Rear Anvil

The tools are mounted on the workbench by bolts. The woodworking bench vice metallic jaws are projected slightly towards the front edge to make the setting and remove a workpiece easy for a user.

However, suppose hammering work is required while dealing with metallic articles. In that case, the models equipped with a rear anvil are also available in the market.

Swivel Base With Rotating Action

As metallic workpieces are hard to rotate or move, a craftsman has to change his position frequently throughout the work activity. To save the workers from this tiresome job, vices made of a swivel base with a rotating capability of about 180 and 360-degrees are also available.

Before utilising bench vice, you must have to provide fix surface, which is usually a workbench. For attachment of bench vice with workbench, two strategies are employed, either by clamping or by bolting.

: HouSolution Universal Vice 360 Swivel Base

How To Install Your Bench Vice Perfectly

In the first method, serrated clamps are used to hold the bench vice firmly over the workbench. The clamp's jagged arms help the bench vice to grasp the workbench surface from above and underneath firmly.

There are two advantages of this method; first, it keeps the bench vice still while working, and second is the freedom of changing its place over the workbench.

Drill Openings For Your Bolts

The second method involves using nuts and bolts for the attachment of a bench vice to a workbench. Most models of metalworking vices come with pre-drilled 4 voids for wrenching four bolts on the workbench.

Once you tightly screwed the four bolts, there is no escape from the metallic workpiece from the bench vice's grasp - ideal for wood planing or drilling. This method is advantageous as there are no damage or injury chances while hammering on a metal piece.

Securing Your Mounted Vice

For maximum output, a bench vice must be fixed and placed well on the worksite before starting a work activity. The part of a bench vice that comes in contact with a workbench is called a mounting interface.

Based on the mounting interface, there are two types of bench vice available in the market. The selection of bench vice depends primarily on the nature of work and the area of your worksite.

: Gardenias O-Shape Swivel Bench Vice Clamp

Vice Workpieces For Small Businesses

The first type of bench vice comes with a mounting interface connected with a workbench through a clamp. These types of vices are suitable for home usage or DIY projects as their handling is quite simple. You just have to adjust the bench vice on the working site by screwing the clamps.

Take Up Too Much Space?

For handling smaller workpieces and small-scale businesses, these vices are used as they require less space. However, one disadvantage of these vices is that you may get hurt if the workpiece gets slipped or the clamp gets lost.

Ideal For Heavier Applications

The second type of bench vices comes with a 'bolt-on mounting' surface and are more suitable for heavier projects. These metalworking vices come with pre-drilled holes, and by screwing four bolts through these holes, you can attach them with a workbench.

Constructed To Endure Impact

These vices are built to endure a lot of pressure and force while working on heavy-duty metallic articles. That's why primarily heavy-duty workshops prefer to use these vices for multiple uses. One disadvantage of these vices is that you have to screw and unscrew the workpiece every time before changing its position.

Woodworking Bench Vice Release Function

The quick-release feature is an essential trait of a bench vice that you should keep in mind while purchasing. Vices with these features make mounting and de-mounting of workpiece comfortable for its user.

Ideal For Those Tiresome Jobs

However, in woodworking bench vices with this feature, you have to manually do this, which is a time-consuming and tiresome job. These quick-release function bench vices are equipped with a finger-operated lever mounted on the front jaw.

Speed Up The Job Process

When force is applied on the lever, the screw thread gets released, and the workpiece is free to rotate or move on the workbench. Most metalworking vices come with this feature in the market as they speed up the working process.

Rotate The Vice On Its Axis

Another useful feature you should consider before purchasing is the swivel base of the bench vice. Swivel base allows you to rotate the bench vice around its axis and extends your reach to every part of the workpiece. This feature is convenient especially dealing with delicate fancy metallic articles and heavy projects.

Using Pipe Vice Equipment

While working, sometimes it is hard to secure a workpiece or using it for plastic pipe cutting in the proper position due to its bulky or delicate structure. The swivel base pipe vice enables you to get the best angle and saves your time by limiting unnecessary unclamping or unbolting of vice.

: Yost Tools Multi Jaw Rotating Bench Vice

180 Up To 360 Degrees Working Requirements

Swivel base also reduces the chances of a workpiece getting damaged by frequent unclamping or unbolting of vice while adjusting the vice position. You can also damage the workpiece by over-tightening while setting it on a vice bench.

Rotational Capacity Importance

In the market, different models are available with the additional rotational capacity of swivel bases. You can select any model with a swivel base of 180 or 360-degree rotating capability based on your working requirements.

Moreover, swivel base strength and integrity are also crucial factors that should be considered while selecting bench vice.

Rotating Heads With Jaws

This a very unique yet handy feature, and very few bench vice models are available with this feature in the market. These rotating heads have two pairs of jaws directly mounted on the central body of the bench vice.

Accommodating Two Sets Of Jaws

Rotating heads save your time and increase your working efficiency by utilising two sets of jaws to hold the workpiece. Metal vices with turning heads are difficult to utilise and used mainly by skilled craftsmen during their work activities. Ordinary bench vices are not equipped with such rotating heads.

: Faithfull 7-Inch Woodwork Vice Screw Dog

Adjustable Woodworking Bench Vice High-Grade Tools

The anvil is a broad flat surface area mounted on the rear of most metalworking bench vices. While dealing with metallic articles, often hammering is required. Therefore, these anvils are mounted on metallic bench vices to save the workers time.

The Impact Absorbing Anvil

Cast iron or solid steel are primarily used in manufacturing anvils to make them resistant to high-impact while hammering. A high-impact absorber anvil increases the durability of metallic vices by absorbing hammering impacts.

Consider Jaw Specifications

Jaws are an integral part of a bench vice. They significantly enhance the bench vice working efficiency by firmly holding the workpiece in place. Mostly, the jaw surface is made serrated to increase its holding grip on metallic articles.

Protecting With Jaw Covers

But the serrated surface of the heavy-duty vice jaw can cause scratches on the delicate articles. So soft jaw covers are mounted on jaws arms so that the workpiece remains unharmed. While dealing with a rough surface workpiece, you can remove these covers to increase jaws' grip.

Mounting Specifications Of Different Vices

Usually, these jaws are decentralised and can be replaced easily when worn out. Some small bench vice models are equipped with jaws that can re-adjust according to the workpiece's size.

These bench vices are used for multi-functional purposes. Therefore, their jaws can be adjusted according to the size and nature of a workpiece.

Other Hardware For Mounting

Some carpenters vice models are assembled and sold in 'all-in-one package' form and not required any unnecessary hardware for mounting. But for some models, you have to purchase mounting hardware separately, which can be a burden on your pocket.

So, always do thorough research on mounting specifications of different models available in the market. In this way, you can get a good quality bench vice for home usage on a reasonable budget. Consider the features we discussed above if you are interested in buying a metallic vice for heavy use.

Workbench Is Not Strong Enough?

Before selecting any bench clamp model, first, consider the integrity and strength-bearing capacity of a workbench that you use. If the workbench is fragile, it will not bear the weight and hammering impacts while using a metallic vice.

Swivel Body And Dual Jaws

Most models have a fixed body and swivel base, which enable you to rotate the vice. But some high-quality models have both swivel body and swivel base along with dual jaws. These woodworking bench vices offer a maximum rotation of jaws holding the workpiece at any angle and in any direction.